Perforated Metals Fabrication

Call us at (800) 341-9800 or contact us using our form to discuss our perforated metal solutions.

Ferguson has over 95 years of experience in perforating a wide range of material types including:

- Copper

- Stainless steel

- Brass

- Tin plate

- Carbon steel

- Inconel

- Titanium

- Monel

- Plastics

- Composite Materials

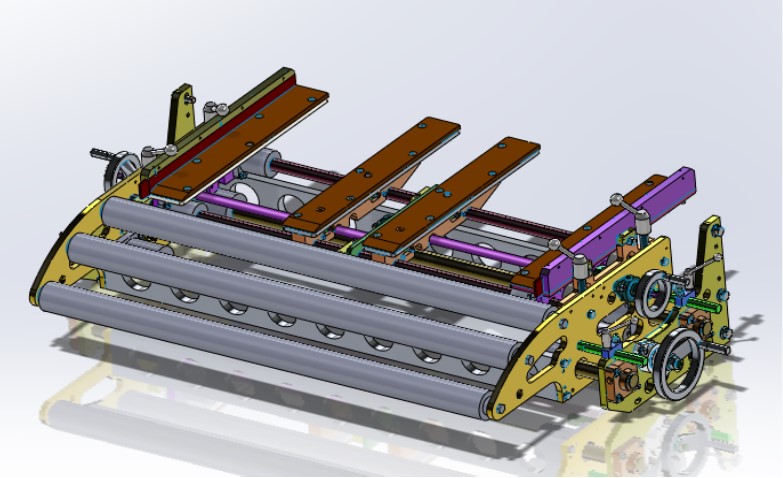

Tooling, perforating, and leveling

Ferguson Perforating designs and manufactures our own tooling, perforating presses, and leveling equipment. We incorporate proprietary capabilities which allows us the flexibility to produce unique patterns that sets us apart from our competition.

Perforating Production Processes

Ferguson excels in small diameter hole perforating. Ferguson’s Perforating Processes are tailored to be the MOST EFFICIENT method of putting hole patterns in either small or large quantities of multi-gage thick materials.

Ferguson is unique in the industry as we produce all tooling and punches in-house. This allows us to provide exact tolerances which control cost, quality, and delivery.

Processes

- CNC, Wire EDM, Centerless Grinding

- Roller Feed Perforating Presses

- Leveling

- Cone Rolling

- Laser Cutting

- Turret Punching

- Design (Product & Tooling)

- Stamping

- Secondary Operations:

- Slitting

- Degreasing

- Forming

- Welding

- Bending

- Shearing

- Tube Rolling

- Fabrication

Perforated materials in stock

We stock raw material (Carbon, Stainless Steel , Brass, Copper, Aluminum)in coils and sheets as well as Semi-Finished Stock.

Materials

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Inconel

- Monel

- Titanium

- Plastics

- Composites

CAD Drawings for your Designs

Our engineers will provide full detailed drawings in both 2D, or 3D format and are committed to “Design for Manufacture” the most cost effective designs by utilizing proprietary algorithms, historical data, and state of the art design software and techniques.

Request a Quote

Request a Quote Contact Us

Contact Us