Perforated Aerospace Metals Fabrication

Ferguson Perforating is both ISO 9001:2008 and AS 9100:2009 certified and is the only US-based perforator to achieve AS9100 certification.

Call us at (800) 341-9800 or contact us using our form to discuss our perforated aircraft metal manufacturing capabilities.

Why choose Ferguson?

- We manufacture perforated metals for aircraft nacelle components such as thrust reversers, acoustical panels, compressor sound liners, fan casings, inlets and exhaust nozzles

- Aerospace-suited metals materials including aluminum, Inconel, titanium and composites

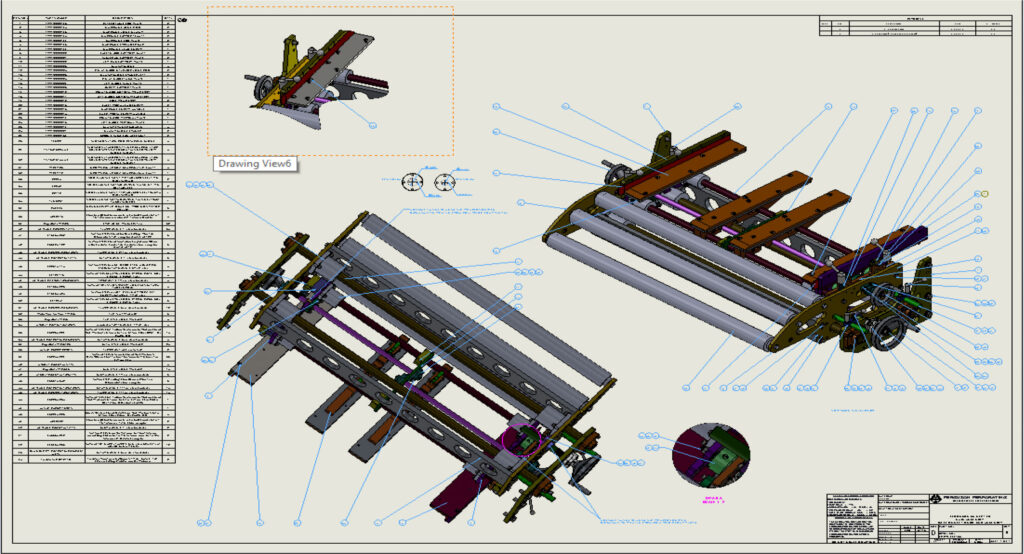

- Production capabilities ranging from perforating sheets to fabricating assemblies

- Perforating capabilities for unique patterns and complicated geometries

- Small-diameter perforations as small as 0.020

- Engineering services and support from for all phases of your project

- In-house design and manufacture of all our own tooling and punches

We have or are currently supplying new parts on the Boeing 747, 767, 737NG, 737 Max, 787 and legacy programs, Airbus A350, A320 and legacy programs, military engine nacelle programs. and continue to provide perforated parts for several Auxiliary Power Unit (APU) programs.

Our engineers will provide full detailed drawings in both 2D or 3D format and are committed to developing the most cost effective designs by utilizing state of the art design software.

Our other perforated metals manufacturing capabilities include perforating, slitting, shearing, leveling, punching and laser cutting.

Request a Quote

Request a Quote Contact Us

Contact Us